REAGENT GRADE ENZYMES

Analytical chemistry plays an important role in the complex issues that are relevant to the environment, public health, food security, and beyond. One of the biggest challenges today is located at the center of these three areas of interest, sometimes referred to as the water-food-energy nexus. Nitrogen and phosphorus containing fertilizers are used for optimal crop growth, but in excess can pollute nearby waterways through runoff, compromising public and environmental health. Nitrogen and phosphorus are essential nutrients for plant growth. As essential plant nutrients, they ensure that crops can grow to their optimal potential, providing food and bio-energy resources. What happens after the nutrients leave the field? They runoff into nearby waterways, and again, as essential plant nutrients, contribute to algal growth as well. When a surge of these nutrients hits a large area, huge toxic algal blooms can occur, creating dead zones in large bodies of salt and fresh water. Excess nitrate in drinking water can pose health threats, especially to infants and the elderly.

As a means of enforcement to protect public and environmental health, the U.S. EPA initiated the Clean Water Act and the Safe Drinking Water Act to set limits on the amount of nitrate, phosphate, and other compounds present in environmental and drinking water. Recently, heavy pressure has been laid on the agricultural industry to limit the input of nutrients applied to fields. Whether it's in national laboratories or out in the fields, the only way to know how much is there and how much should be added is to first test and know how much of each compound is where.

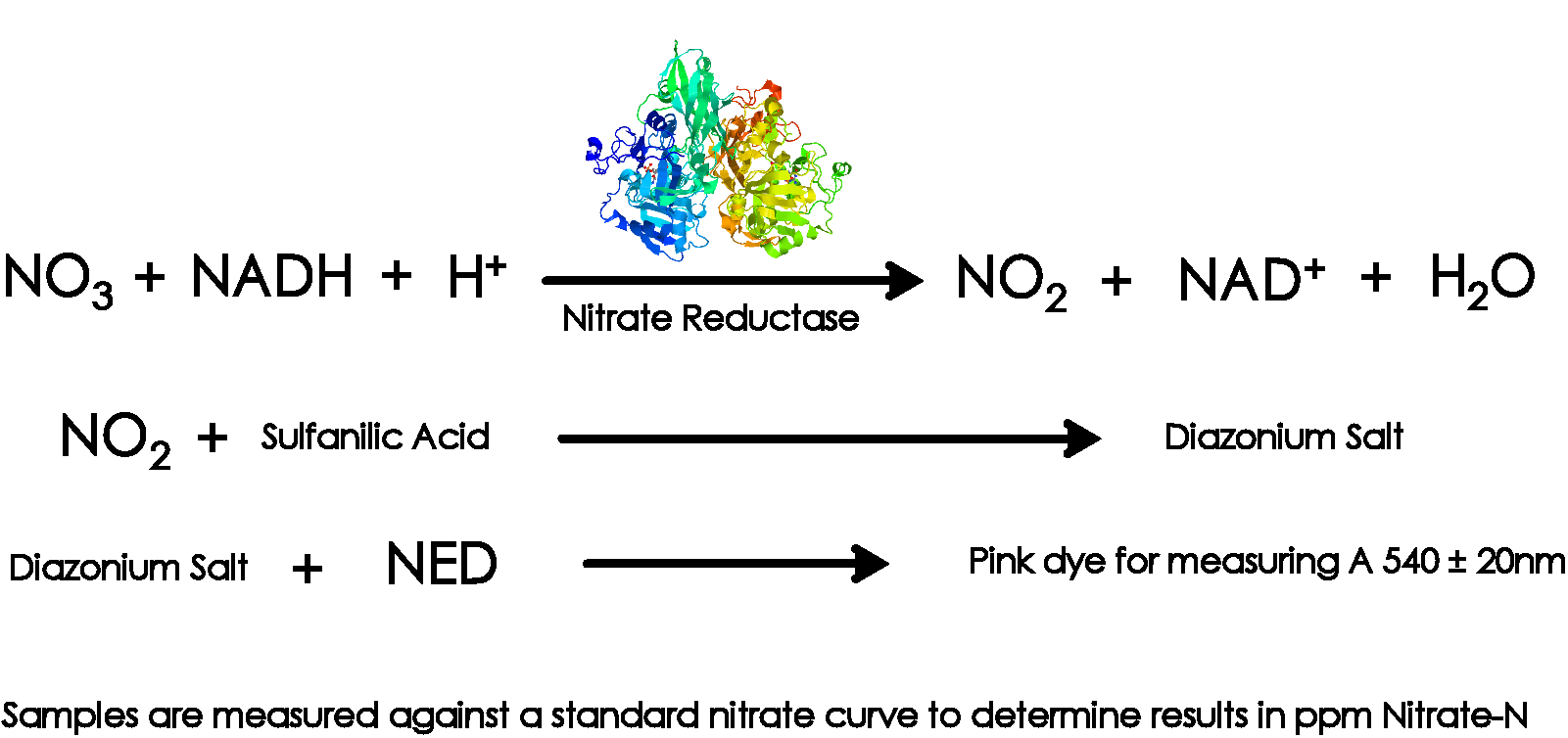

The traditional method for measuring nitrate is the cadmium reduction method, which uses the toxic heavy metal cadmium. We've invented a new method to quantify nitrate that uses an enzyme. This method is safer, greener, more accurate, sensitive, and reliable. Enzymes are incredible biological machines that happen to make excellent tools for analytical chemistry.

Why reagent grade enzymes for analytical chemistry?

- SELECTIVITY Enzymes are able to find their substrate in complex mixtures

- SPECIFICITY Enzymes only react with their substrate in the presence of other compounds

- SENSITIVITY Enzymes find even the tiniest amount of their substrate in a scarce sample

- SAFETY Enzymes react in gentle conditions, are non-toxic, and environmentally benign

enzymes make the world go 'round

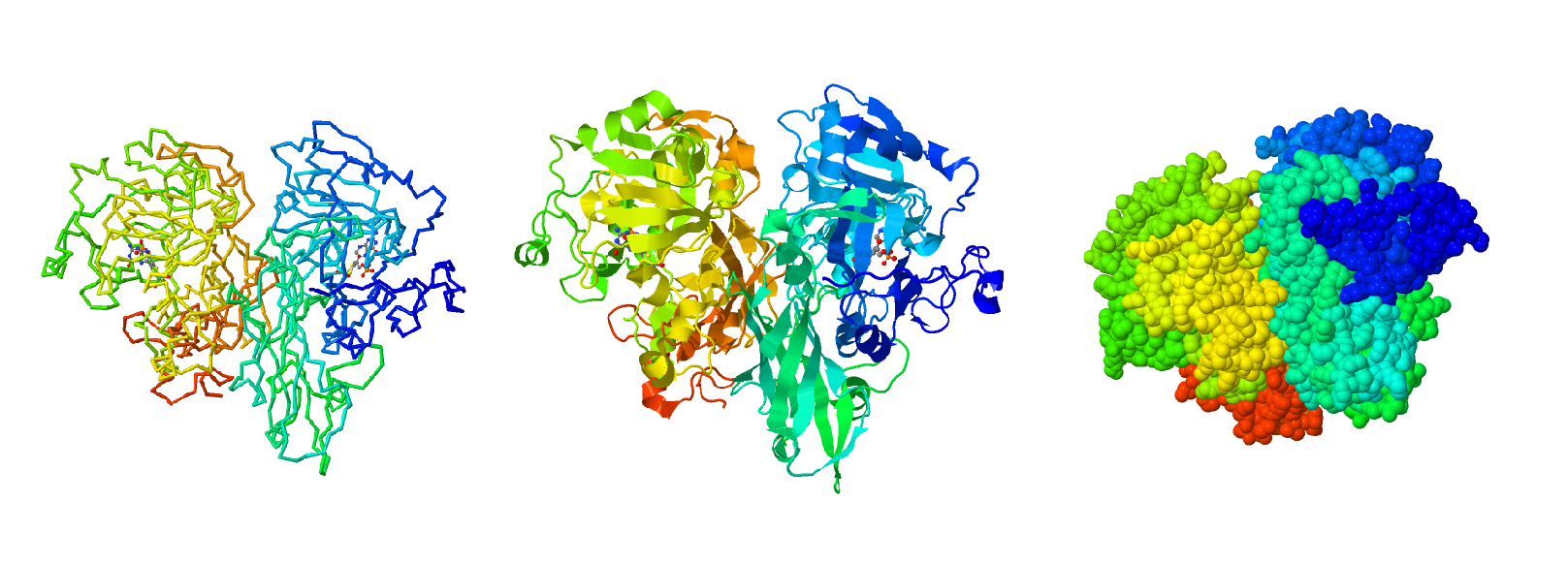

Enzymes are protein catalysts that speed up the myriad of biochemical reactions that make life possible. Enzyme reactions occur in gentle, biological conditions: no toxic solvents, high heat or pressure, no heavy metals involved, no side effects. They're the naturally occurring biological robots that are programmed to carry out highly specific tasks under very specific conditions in all living systems. Enzymes are made of a long string of amino acids, the building blocks of proteins, that react with each other to give shape to a three dimensional structure. Each enzyme only reacts with a specific starting molecule called a substrate using a highly specialized and uniquely shaped binding site - like a lock and key, a hand in a glove, or two fitting puzzle pieces. Once their substrate is bound, catalysis converts the substrate into a new molecule, called a product, which occurs a million times faster than it would without the enzyme. After this is complete, the enzyme releases the newly formed product and is ready to begin the process again, which usually occurs within milliseconds. Because of this unique and highly specific process that occurs under biological conditions, enzymes are the optimal tools for green analytical chemistry: accurate, reliable, specific, sensitive, environmentally benign, biodegradable, and non-toxic.

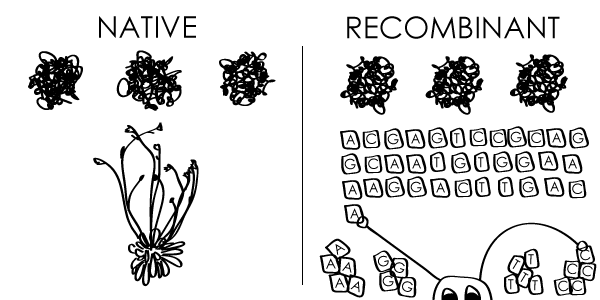

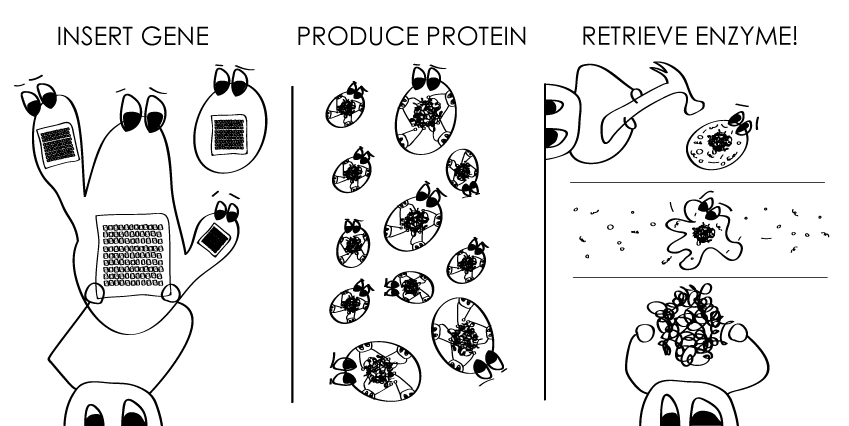

Native enzymes are the naturally occurring catalysts that help all types of biological systems perform their routine functions, such as food digestion, DNA replication, enzyme production, and more. Although these native enzymes work seamlessly in their respective biological systems, they might not be practical to be used as tools for other projects. Plus, it requires a lot of work to get the enzymes from their native source, and variability between copies of the same enzyme is common. Even a change to one amino acid can be detrimental to the enzyme's structure and ability to perform its duties. This is where recombinant protein technology comes in. If the gene sequence of the desired enzyme is known, scientists can manipulate the DNA to craft a recombinant version that has certain desired traits. The recombinant DNA is then inserted into tiny organisms, mostly yeast or bacteria, to use that cell's machinery to produce the same enzyme every time.

NECi manufactures recombinant enzymes using reagent grade sugars, salts, and buffers in a tightly controlled closed fermentation system. This guarantees lot-to-lot consistency between batches of enzymes, providing truly reagent grade analytical tools to be used in our products.

HOW THE NITRATE ASSAY WORKS

Enzyme Based Analytical Chemistry

Test kits for laboratories, agriculture, homeowners, and more

334 Hecla Street, Lake Linden, MI 49945

Phone: (906) 296-1115

Fax: (906) 296-8003

Sales: sales@nitrate.com

Tech Support: tech@nitrate.com